Our non-mag materials

SBO, the global market leader, produces non-magnetic, high-strength, and corrosion-resistant alloy for the oilfield industry.

| Dimensions | Solid Collar (SC) | Drill Collar (DC) |

| Length |

up to 374 in | up to 374 in |

| Outer diameter | 3,5 in – 18 in | 3,5 in – 18 in |

| Inner diameter | 1,9 in – 3,2 in |

Note: The standard drill collar length is 372 inches. Production outside the standard dimensions is possible upon request.

Properties that characterise our steels

High Strength

High Corrosion Resistance

Non-magnetic

Excellent Machinability

Excellent Weldability

In-House Testing in Austria

We test the chemical composition, relative magnetic permeability and fatigue strength for each melt.

In addition, we carry out various examinations and tests on each rod:

- Tensile test

- Notched bar impact test

- Hardness test

- Acid test (as per ASTM A 262 – Practice A)

- 100 % volumetric ultrasonic NDT

- 100 % volumetric hot spot test

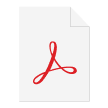

Pitting Corrosion Chart

At our company, we offer a range of advanced steel alloys designed for superior performance in various applications. Our SBO non-magnetic steel stands out due to its exceptional purity and specialized processes, including cold forging and surface finishing, providing unparalleled resistance to stress corrosion.

Key Features of SBO Non-Magnetic Alloy:

High Purity:

Our steel undergoes rigorous processes ensuring a high degree of purity.

Higher Chromium and Nitrogen Content:

Specialized Treatment:

Cold forging and surface finishing techniques enhance stress corrosion resistance.

Competitive Range of Alternatives

Data Sheets Sample

P 530

P 530 HS

P550

P 690

P670

P750

P650HS